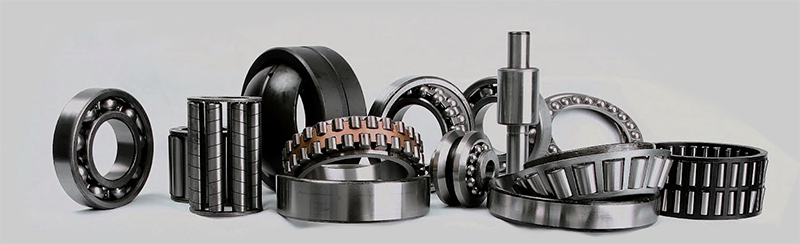

Different types of Bearings

Different types of Bearings:

1- DEEP GROOVE BALL BEARINGS

This kind of bearings because of their simple design, non-discrimination and theabilityto operateathighspeedshas a wide range of application. They are produced in some types such as single row (shape in previous page), double row (above shape) and single row with ball groove.

2- SELF-ALIGNING BALL BEARINGS

It has two rows of balls and a common outer ring which the ball groove has a curve shape and this issue causes self-aligning feature for ball bearing that it is shaftin deviation and non-alignment time.

3- ANGULAR CONTACT BALL BEARINGS

As thecontact angleis greater, the tolerationaxial loadonthebearing will be added. The inner and outer rings in this bearing relative to each other make an angle which provides the possibility of radial and axial load tolerating simultaneously. As thecontact angle in ball bearings is greater, its axial load tolerating will be increased. The different productions of these ball bearings are: single row and double row Contact ball bearings and Four Point Contact ball bearings.

4- CYLINDRICAL ROLLER BEARINGS

The roller bearingsaredesignedsothat one of theinnerorouterringsdoesnot have one ortwo sideedgesand thusthe roller bearing hastheability to separate. In cases such as handling and bringing the roll bearings especially when the compliance should be interfering, it causes to work facility. In addition to the toleration ability of heavy loads, these bearings can rotate in high speeds. A kind of bearing which its number begins with NU, the lower ring is without edge and it can be separated and in the other kind which begins with N, the above ring is without edge. In some cases such as expansion of the longitudinal shaft because of heating, prevents from tension by possibility of rings moving along the axis. In other type which begins with NJ, the inner ring has an edge in one side; therefore, it is possible to change the axial place in one side. This type of design helps to install the separable bearing easily at first, then by locating a loose edge in front of it, the roll bearing can be fixed from two sides along the axis.An angle ring which indicated by HJ can be used instead of separable edge. Amount of permitted non-alignment in roll bearing series 10, 2, 3 and 4 is four minutes and in series 22 and 23 is three minutes. Cylindrical roller bearings up to 150° c can be used without changing in dimension. Their ball window is produced in any size and in different polyamide,steelandbrass.

5- Needle Roller Bearing

They are with the crust stretched and open end with crust stretched and closed end needle roll bearing with inner ring, needle roll bearing without inner ring, the roller are in the cylindrical shape, but their diameter is smaller relative to their length but despite of this feature, they have high load tolerance and they are useful for application in small spaces.

6- SPHERICAL ROLLER BEARINGS

These roll bearings have two rows of roller in one joint groove that is curving in shape in the outer ring and two grooves in inner ring make angle relevant to bearing axis. The bearing has a self-alignment feature so it is not sensitive to non-alignment of shaft and in addition to tolerate radial load, it tolerate axial load from both side. Its rollers are long, thick, and symmetrical and in excessive numbers which these features caused extraordinary high tolerance against forces.

7- Taper Roller Bearings

As theangleis greater, the axial load tolerance of bearing will be increased. This bearing has conical roller groove in above and lower ring and the rolling part is in conical shape. This design makes the bearing suitable for complicated load tolerance (radial & axial). The ability of axial load tolerating depends on groove angle of outer ring (a).

8- Thrust Ball Bearings

These bearings are produced in types of Single direction and double direction.

8.1- Single Direction Thrust Ball Bearings

These bearings are suitable for axial allocating and load tolerance from one side and never should be applied for any radial load. Ball bearing includes of a shaft washer with ball groove, shelf towards balls and a housing washer with ball groove. The housing washer upon its application and requirement can be made in the flat or sphered form and in second status if used a seating washer, the bearing can be complied with first non-alignment of shaft. Whereas the ball bearing is separable, their installation will be simple.

8.2- Double Direction Ball Bearings

These bearings are suitable for axial allocating in shaft and load tolerance from both sides. And similar to previous type never should be applied for any radial load. Ball bearing includes of a shaft washer with two balls groove, two shelves towards balls and two housing washers with ball groove. The housing washer can be made in the flat or sphered form. These ball bearings are separable. Different types of Thrust ball bearings are produced with steel and brass shelves.

9- Needle Roller Thrust Bearings

These bearings can tolerate a heavy axial load while they are not sensitive to shock loads, they need minimum axial space for installation. These roll bearings can tolerate the axial load from one side. The bearing includes of housing washer, shaft washer and a series of shelves and rollers. The series of shelves and rollers can be applied only with a thrust washer and in this case the place of bearing should be had enough stiffness andsurface smoothness.

10-Spherical Roller Thrust Bearings

In these bearings the angularity form of roller groove relevant to axis make them suitable for tolerating radial and axial loads. The other significant feature is self-alignment ability that causes insensitivityof roll bearings towards shaft non-alignment. They are separable, the shaft washer with shelf and rollers made one part and the housing washer made the other part. Spherical rollersin these kinds of roll bearings have non-symmetrical status; the excessive number of these rollers with special design of roller groove causes their extraordinary high strength against axial loads while they have relatively high rotational speed. There are special designs (E) which have higher load tolerance relevant to ordinary types. Some series of these roll bearings produced with window-type steel shelves and most of series produced with machined brass and steel shelves that these shelves for allocating in proper situation will be set by a bush which located in the hole of shaft washer. As said before, the spherical roller thrust bearings has self-alignment feature.

11-Cylindrical roller thrust Bearings

These roll bearings are suitable for tolerating heavy axial loads. In addition, they are not sensitive against shock loads,they have high strength and need a small axial space for installation. They made in single row type and can tolerate axial load from one side. Their design is simple and includes a shaft washer, a housing washer and a shelf with some rollers. When the allocating place of roll bearing is suitable, the housing and shaft washers can be omitted and used from shelf itself and rollers, but any way their locating place should be hard. Therefore, in general, whole of ball bearings have a special number and each part has a separate number.

Sanatgarane Roll Ring Parsian Company

Import & Export of different types of Bearing